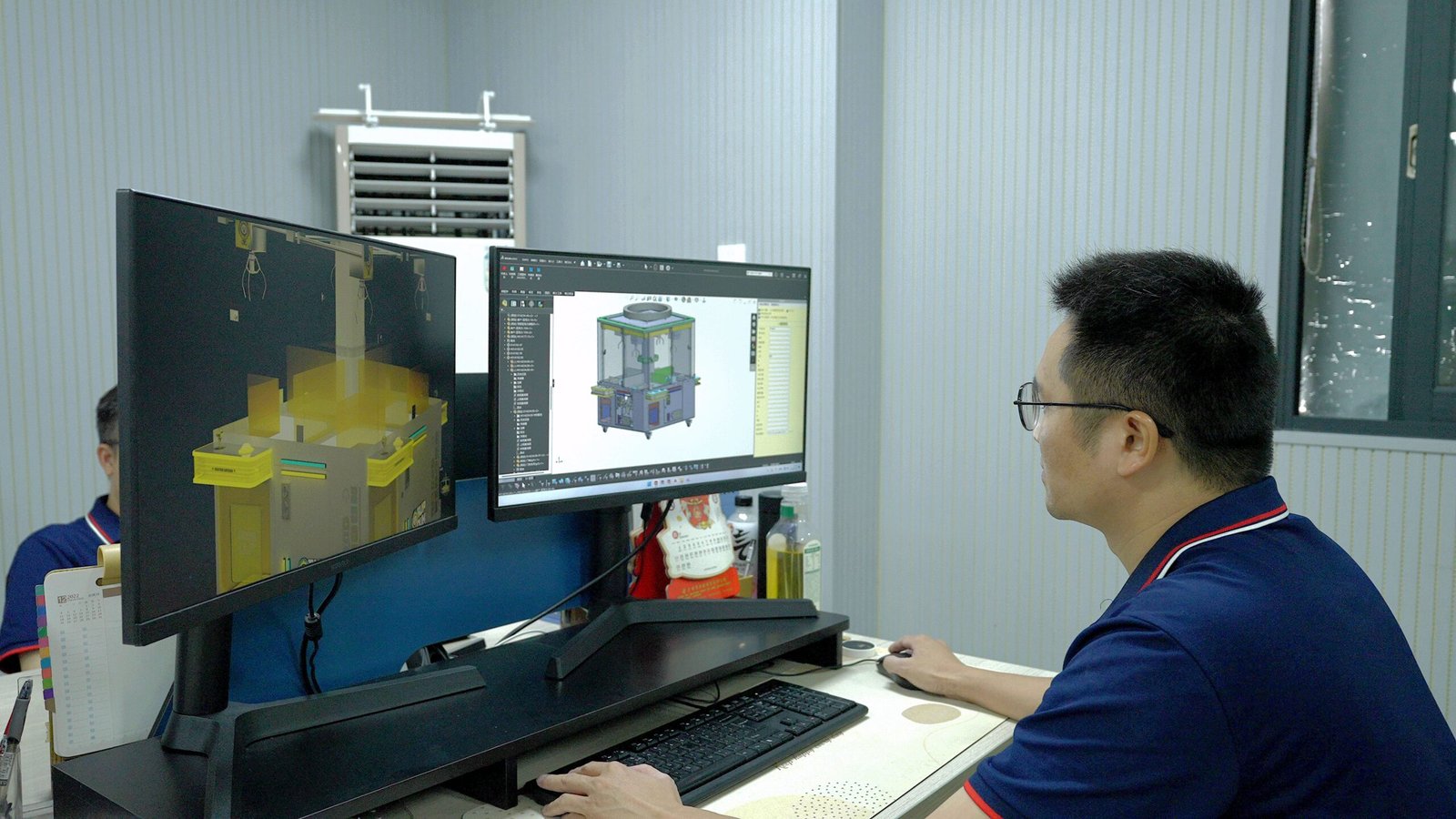

Experienced customer service personnel respond timely and follow up. And our professional engineering team is always ready.

Skilled engineers handle complex projects and provide solutions. All kinds of sheet metal enclosure OEM services are available.

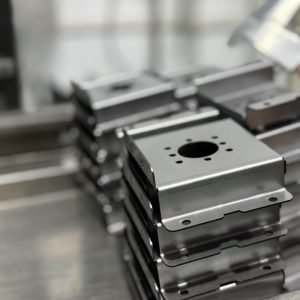

On-Demand Production:Rigorous QC department. High-Precision Dynamic-Range:Advanced sheet metal processing machines.

WHO WE ARE?

JUSHUN IS The Leading Industrial Factory In CHINA.

- Jushun covers an area of 15,000 square meters and employs a team of 200 experienced employees.

- Advanced Equipment:Dozens of advanced laser cutting equipment, including high-power fiber laser cutting machines, achieve high-precision sheet metal cutting. High-precision bending equipment ensures precise and aesthetic metal bending.

- Specializing in the design & engineering of functional products, such as sheet metal parts or enclosures for various industries, including medical, automation, arcade games, public equipment, and new energy.

- Target customers: B2B clients in software design, product development, and equipment manufacturing who require structural design and sheet metal hardware OEM production services.

Metal Bracket

Metal Enclosure

Metal Shields

Metal Accessories

Production process

The scientific and standardized production process ensures that every link from order receipt to product delivery is efficient and controllable, guaranteeing product quality and delivery time

Why choose us ?

- Rapid Turnaround:Line scale management ensures rapid lead times while maintaining high quality standards.

- Rapid prototyping: A powerful engineering team and production department to meet all your customized requirements for sheet metal parts or sheet metal enclosures.

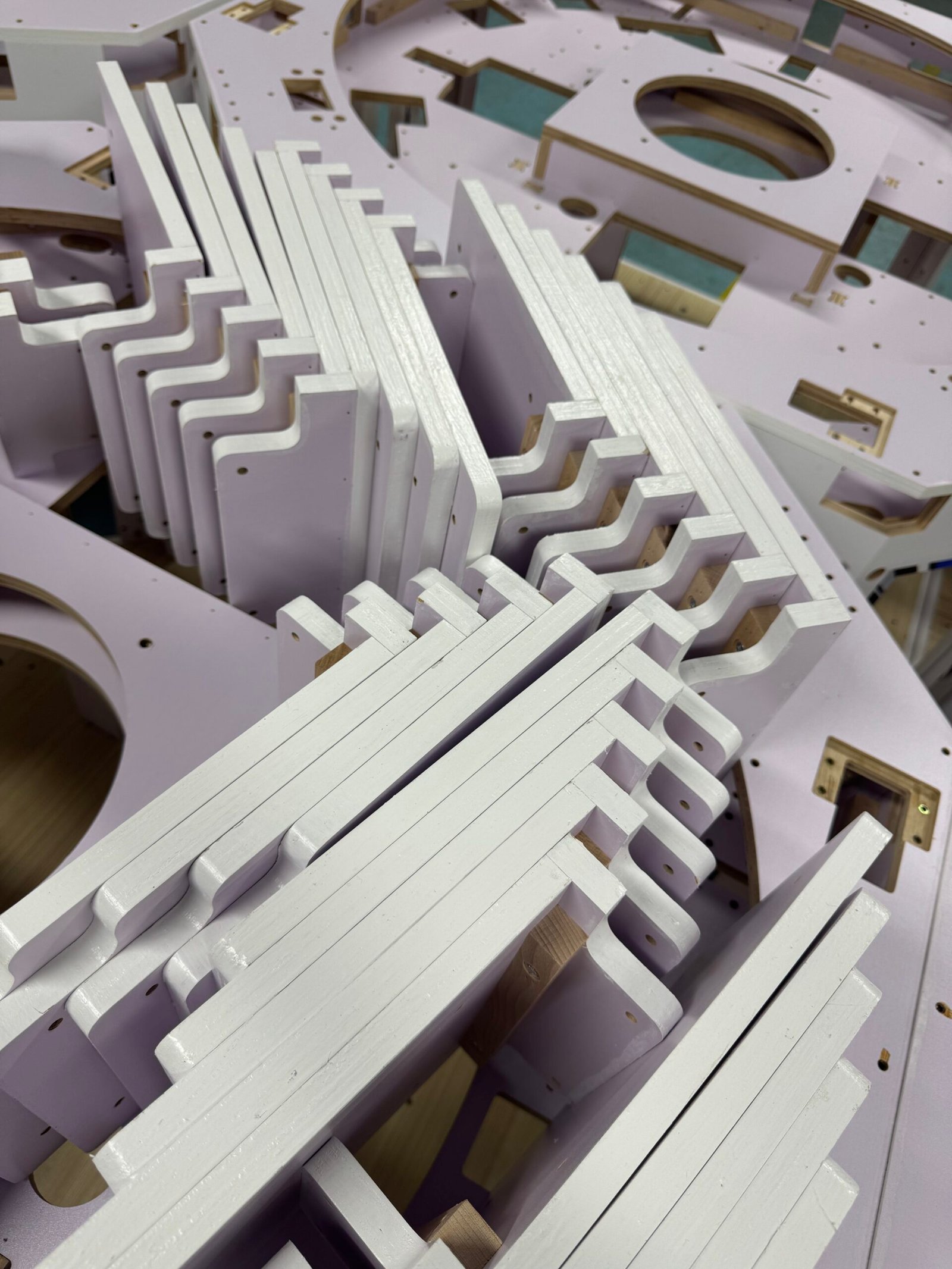

- Wide range of material options: Including not limited to steel, aluminum, copper, brass, titanium and many others, even various types of wood boards (medium density fiberboard, multi-layer plywood).

- Unique surface treatment: Reliable traditional spraying treatment, and sheet metal products undergo multiple wash tank treatments to ensure durability and color stability.

- It can handle various complex sheet metal surface problems. Common treatment methods include anodizing, powder and paint coating, E-coating, passivation and vacuum coating, such as PVD, CVD and NCVM.

THE TECHNIQUES WE USE

Focus on sheet metal fabricating to ensure the high-precision, high-quality and efficient delivery of products.

The Sectors We Operate In

Game Consoles Enclosure:

Jushun can produce arcade machine shells with wooden frames or sheet metal structures, including types such as pinball machines, claw machines, and children’s amusement machines. One-stop service from the disassembly of drawings, to structural analysis, sampling, and mass production.

Public Facilities:

We produce electrical boxes of various grades (IP, NEMA), communication equipment enclosures, various metal structural components for the construction industry, or lighting system enclosures to provide hardware protection for equipment in various industries.

Software Equipment Protection:

Jushun collaborates with major software development companies to integrate software and hardware and launch its products to the international market. 3D mobile phone case printers, vending machines, self-service kiosks, etc.

New Energy Industry

With the development of the energy industry, the EV charging cabinet shells and new energy vehicle plate parts made by Jushun have been favored by international purchasers.

Medical Hardware:

Jushun has cooperated with many well-known medical equipment manufacturers and specializes in providing various equipment casings or sheet metal parts used in the medical industry.

Furniture Industry:

Jushun, in collaboration with furniture companies, produces cabinets, stands, shelves, and metal kitchenware that meet customers’ demands for high precision and standards of products.