Techniques

When you need experience, we have it covered.

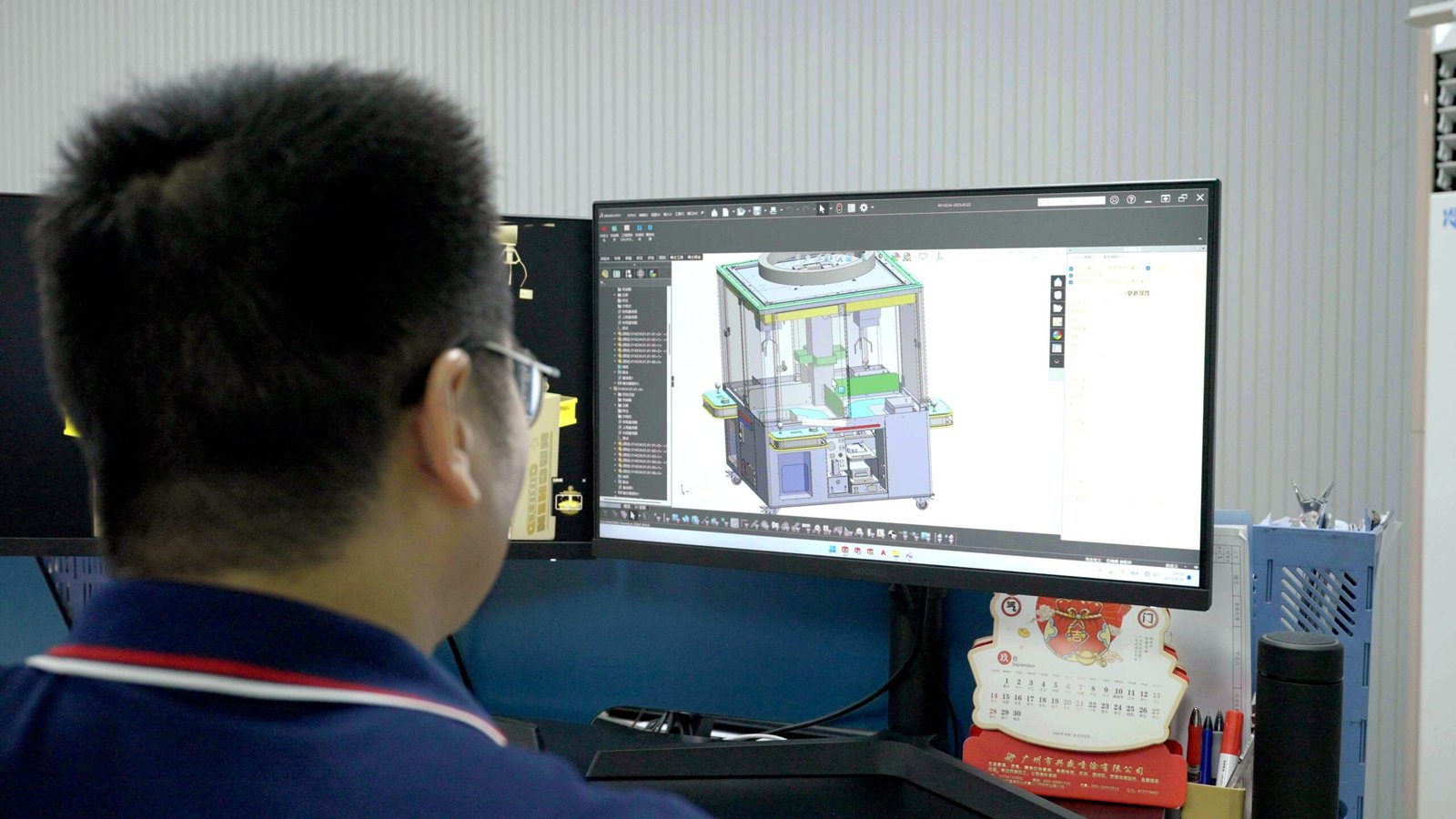

Design & Engineering Support

-

Professional drawing software is adopted for product design and optimization -

Provide DFM (Manufacturability Analysis) to ensure that the design meets production requirements 3D modeling and simulation, precisely matching customer needs.

Laser cutting

-

Equipped with a high-power fiber laser cutting machine, it can process various materials such as stainless steel, carbon steel and aluminum plates -

The cutting accuracy reaches ±0.1mm, suitable for complex contours and fine structures

- Support efficient cutting of thick plates (0.3mm to 100mm), reduce burrs and improve edge quality

Press the brake/Bend the metal

-

The CNC Press Brake is adopted, and the bending accuracy reaches ±0.1mm -

Supports complex bending angles (30° to 180°) to meet diverse structural requirements

- Equipped with multiple molds, it is suitable for metal forming of different thicknesses (0.5mm to 12mm)

Welding (argon arc welding, spot welding, CO₂ shielded welding)

-

Equipped with a high-power fiber laser cutting machine, it can process various materials such as stainless steel, carbon steel and aluminum plates -

The cutting accuracy reaches ±0.1mm, suitable for complex contours and fine structures

- Support efficient cutting of thick plates (0.3mm to 100mm), reduce burrs and improve edge quality

Powder coating (Surface Treatment)

Provide electrostatic Powder Coating to enhance corrosion resistance and aesthetic appeal.

- Multiple colors (Pantone color card matching) and special effects (matte, texture, etc.) are available for selection.

- Pretreatment ensures strong adhesion and long service life of the coating.

Additional value-added processes

Machining: CNC milling/lathe processing, handling high-precision metal parts

Stickers & UV printing: We offer customized services for brand logos, signs, functional stickers, etc

Acrylic molding & processing: Supports PMMA (organic glass) cutting, engraving, and heat bending forming