The first step in machining for many industries is sheet metal cutting. CNC cutting is a very common processing technology in our current production processes. But do you think your understanding of CNC cutting is comprehensive? Understanding CNC cutting in different dimensions may help you come up with appropriate solutions when you encounter machining problems.

What is CNC Cutting? (Basic definition)

CNC (Computer Numerical Control) cutting is an abbreviation for computer controlled cutting. Operators use CAM software or G-code after designing on computers. Upon receiving these commands, the machine will follow the programmed lines to cut the material in the predetermined size, shape, and with the required accuracy. This not only minimizes errors that are likely to occur during operation by human beings but also realizes higher speed and stability in the production process.

CNC Cutting vs CNC Machining (clarify the overlap & distinction)

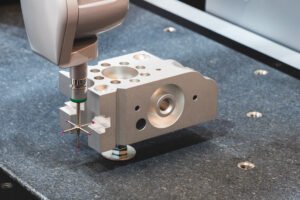

CNC cutting and CNC machining have similarities as well as distinct differences. By definition, both involve a process in which an operator creates a design in computer software and then transmits the instructions to a machine. However, CNC cutting only performs two-dimensional contouring on a material to separate it. CNC machining, on the other hand, involves more complex tasks beyond cutting, such as milling, drilling, turning, and tapping. While CNC cutting solves two-dimensional problems, CNC machining helps you solve complex structural problems, even in multiple dimensions. Many of the precision parts inside the machinery we use are manufactured using CNC machining.

Brief history & evolution of CNC technology

1940s–1950s

- NC (Numerical Control) was born.

- In the early days of computer numeric control, an operator would punch in data to control the machine tool’s motion.

1952

- The US Air Force worked with MIT

- Inspired by a Cincinnati Hydrotel milling machine they began working on to develop the first NC (numerically controlled) milling machine.

- This was the launch of automated production.

1960s–1970s

- Computers made their way into the numerical control systems.

- CNC ushered in better, faster, more agile, more accurate automated production.

1980s

- CAD/CAM software became widely available.

- Design and machining were much more tightly integrated and CNC technology evolved very quickly. It facilitated the production of intricately shaped parts.

1980s–1990s

- The advent of the multi-axis machining center

- Three, four, and five-axis machines are becoming more and more common, which is helping to reduce the time that is required to machine complex geometries.

2000s–Present

- Intelligence and Automation

- What is CNC with CNC simulation, networking, automation loading and unloading, and robotics. This has promoted the rise of smart manufacturing and Industry 4.0.

How to Identify CNC Cutting Types

The key to understanding what CNC cutting is is to understand how people define it. CNC cutting involves different tools, different types, and even different processes. Only by understanding these aspects can we truly understand CNC cutting. Here are a few dimensions that we use to distinguish CNC cutting, which we hope will be helpful to you:

Types of CNC Cutting Machines

According to the cutting style, here we divide the CNC cutting machine into four types, while all of them have their own features as follows:

- Firstly, we shall introduce CNC flame cutting machines. CNC flame cutting is an older and very slow method of cutting. CNC flame cutting can cut thicker materials than plasma cutting, but it has low cutting efficiency, needs to be preheated, and the material will be deformed after cutting, so many plants use plasma cutting machines。

- For this reason we will concentrate on CNC plasma cutting machines. Plasma cutting machines can cut all kinds of thickness of 6-6mm palette, all kinds of the shape of the plane, complex graphics, drilling holes.Hole cutting is good quality. Plasma cutting process, unlike laser cutting, generates noise, dust, light and other toxic and harmful gases, which must be implemented by under water。

- Moving on to the slightly more costly options for CNC cutting machines are CNC laser and CNC high pressure water jet cutting.Typical application of CNC laser cutting regarding high frequency sheet metal cutting, there is one type of cutting that is the most commonly used: CNC laser cutting! It has high accuracy and efficiency despite the complexity of the part, however, it is limited to thin and medium thickness sheet metal, and the efficiency is low when thicker plates are processed.

- CNC high pressure water jet cutting is another possibility. It is an accurate tool with no thermal stress, no heat-affected zone, and less pollution (waste water and abrasive residue treatment are necessary). Moreover, the cutting speed, efficiency and cost of CNC water jet cutting are low.

From the above, we can see that each type of CNC cutting machine has its unique features: flame cutting is the cheapest one, plasma cutting is moderate, laser cutting is more expensive, water jet cutting most expensive. At the time of buying or makinging selection of a CNC cutting machine, the choice of material such as the thickness of the sheet metal is a factor you should consider. Of course, you should also keep your company’s requirements or pros and cons in mind.

Applications of CNC Cutting

Conventional understanding suggests that CNC cutting is just one step in the manufacturing industry. It can be applied across various fields depending on the raw materials and subsequent processing steps. Here, we’ll analyze the different areas in which time-space cutting is categorized by material:

Metal materials:such as aluminum, steel, copper, and stainless steel, are widely used in the machinery manufacturing, aerospace, and automotive industries. From large frames to small precision internal components, even the popular new energy charger housings, these are all CNC-cut metal parts.

Plastic materials:such as plastic, are lightweight alternatives to metal, offering excellent strength and chemical resistance. Many medical device housings are made from CNC-cut plastic sheets.

Composite materials:such as carbon fiber and fiberglass, are increasingly popular for their strength and lightweight properties. You’ll see examples of composite materials in advertising displays and custom logos.

Non-ferrous metals:such as copper and aluminum alloys, are widely used in the electrical industry for their electrical and thermal conductivity.

CNC Cutting Processes Explain

Generally speaking, the CNC cutting process you typically see requires the following three steps to be considered a complete operation:

- Preparation: This is crucial for ensuring accurate and error-free cutting. First, select the appropriate cutting tool based on the material being cut. At this point, you should check that the tool is functioning correctly. After securing the material to the machine, adjust its position.

- Processing: Use CAD/CAM software to create the CNC program, generate G-code or a CNC program that the machine can understand, and confirm specific parameters such as tool paths, speeds, and feed rates. Next, set up and debug the machine according to the program, calibrate the zero point, set cutting parameters, and confirm the safe zone. Once these steps are complete, processing can begin.

- Inspection: After cutting, perform dimensional and quality inspections on the material to ensure it meets standard requirements. Any workpiece that does not meet these requirements must be reworked promptly.

Why CNC cutting matters in modern manufacturing

Many people may ask why CNC cutting should be used instead of manual cutting? After understanding the origin, application and process of CNC cutting, it should not be difficult to see that CNC cutting has become an irreplaceable process in the processing industry. In today’s world where efficiency is everything, automation is called a trend for certain reasons:

First, CNC cutting can achieve precision that is simply unattainable by manual cutting. All data is meticulously analyzed using design software, resulting in minimal cutting errors and far superior precision to manual operation. The more advanced and precisely calibrated the machine, the more accurate the cutting results.This is extremely important in industries with high precision, such as aviation, where even a very small cut part cannot have an error, otherwise the entire test project may fail.

Another issue is economic benefits. Errors in CNC cutting are rare, thus avoiding material waste caused by operational failures. Furthermore, CNC cutting allows for a comprehensive analysis of the material layout to be cut during the design phase, effectively utilizing all available materials.

Furthermore, by replacing much of the manual labor with automated equipment, CNC cutting can handle more complex edge processing. Because custom orders often require unusual shapes, complex CNC cutting processes (such as lasers and water jets) can meet these requirements.

Finally, as long as the CNC machine has sufficient power, it can perform cutting work non-stop, which will be of great help to you when you are facing batch orders, because CNC cutting is highly efficient.

CNC Cutting and the Future of Machining

The manufacturing industry is ever evolving at the speed of technology. The cutting was started in a simple 2D manner. Facets of CNC Machining The advancement of computers later made CNC cutting, while the development of CAD/CAM software made CNC milling more accurate. Looking back on the history of CNC cutting, it is a high-end product that is updated continuously. The fate of products combined is convergence. My response:Automation is in progress. I believe it’s still a long road ahead and the different technologies are going to be merged and they will help one another. Already, we have seen the advent of robotic arms in a number of manufacturing processes, i.e. loading/unloading of materials, working the cutter. These developments are rapidly improving efficiency and versatility of the production environment.

Conclusion

In short, CNC cutting is more than just a way to shape sheet metal – it is the core technology that drives modern manufacturing forward. By understanding its types, applications, and future trends, manufacturers and engineers can make more informed choices, reduce errors, and stay competitive in a rapidly evolving industry.

FAQs

Precision CNC Machining vs. Manual Machining

The entire article above has been devoted to discussing the benefits of CNC machining. Many people wonder: Is manual machining necessarily inferior to CNC machining? For now, the answer is no. It’s undeniable that precise CNC machining has brought substantial benefits to the manufacturing industry. While we’ve discussed which types of CNC cutting are less expensive, when it comes to small-batch orders or simple parts, labor costs are still lower than machine operation. In other words, while machines are handling large-scale, complex machining operations, simpler tasks can be performed manually, maximizing efficiency.

What is the Difference Between CNC Cutting and Laser Cutting?

This question actually comes down to choosing the right cutting method. Laser cutting offers the advantage of precise cutting without contacting the material. This means it reduces physical wear and tear on the material. CNC cutting (milling), on the other hand, is more suitable for more complex parts, such as 3D components. Consequently, different cutting methods require different tools, which can lead to operational difficulties and time consumption.