Leading in the aluminum enclosure industry

The aluminum enclosures produced by Jushun are divided into many categories. Metal enclosures with extruded aluminum enclosures, sheet metal enclosures and aluminum diecast enclosures are our more popular products. Due to different application fields, the enclosures are designed into various different shapes. The inclined roof is for drainage, the shutters are for better heat dissipation, and the transparent viewing window is for the convenience of checking the internal equipment at any time. If you have different ideas about the enclosures, please feel free to contact us!

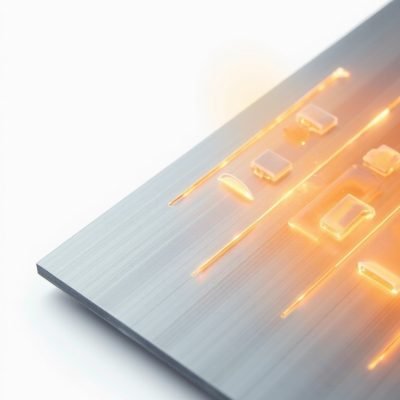

Aluminum Enclosure

Aluminum housings are made of aluminum plates. They can be used to protect sensitive instruments, to arrange cables in wire boxes, or even to offer a degree of inherent EMI/RFI attenuation for devices and applications. Their construction is actually very simple but useful:

- Aluminum plate: grounding stud is provided on the enclosure (smooth, flat welding)

- Knockouts, cutouts, and holes are optional

- Lip cover structure, excludes water and dust ingress

- Brackets provide for enclosure mounting. (Mounting bracket)

- Hinged door-can be opened 180° (with connection studs on the door)

- Door latches: added safety of quarter turn slot (316 stainless steel) requiring

- Seamless- waterproof gasket

- Galvanized inner panel-installation bracket

Product catagory

Hinged metal box

Heatsink enclosure

Metal electrical box

Instrument enclosure

Waterproof metal

boxes

Hydraulic or pneumatic control housings

Electrical junction

boxes

Terminal wiring enclosures

Feature box

Anti-corrosion/anti-magnetic

Aluminum has its own unique properties like many metals. It is corrosion-resistant and can block the entry of water vapor in a humid environment, thereby protecting the internal equipment. In addition, anti-EMI makes aluminum housings widely used in the communications and electrical industries.

Durable

The durability of aluminum is mainly due to its unique physical and chemical properties. Aluminum reacts with air to form a dense film (about 2-10 nanometers thick). This film has stable chemical properties and can effectively prevent further oxidation of the internal metal, so its service life is also long.

Polished and professional appearance

The aluminum plate is silver-white, with a frosted surface, or a polished or powder-coated surface treatment, so we can supply any aluminum housing you want, which is in line with our goal, which is to provide customers with one-stop processing services.

Aluminum enclosure VS. Steel enclosure

In sheet metal processing, aluminum and steel are our two most common materials. The difference between them has always been a problem for buyers to consider, because only if you can easily distinguish the difference between them, you can choose the most suitable product for your industry.

Lightweight substitution

Our aluminum enclosures are becoming popular because of their low density and light weight. If your industry involves transportation (electric vehicles) and aerospace, then lightweight is a very important purchasing consideration. Although aluminum shells are more expensive than steel, aluminum can bring you product empowerment that steel cannot.

Excellent thermal conductivity

Aluminum has good thermal conductivity. Jushun’s aluminum shell will be combined with a heat dissipation structure design, which can further highlight the thermal conductivity of aluminum and protect the equipment from cooling down to a certain extent during high-temperature operation.

Easier to machine

Aluminum is easier to process than steel with higher hardness, which means that CNC, stamping, and bending are easier to operate. So Jushun’s aluminum enclosures have more choices in appearance. We can make aluminum products with different shapes and structures according to your needs.

We have modular designs, such as flange brackets + waterproof gaskets + cable racks, which can all be customized.

In order to enhance hardness and wear resistance, multiple treatments such as electroplating, sandblasting, polishing, stickers, etc. are optional.

Although plastic plates are more affordable, aluminum plates have metal properties, such as anti-magnetic, anti-corrosion, durability, and thermal conductivity, which are far beyond the reach of plastic.

We have an excellent customer service team. If you are ready with ideas, plans, or design drawings, please contact us and we will make a customization and production plan for you as soon as possible.